+86-510-88852188 sales@bdctec.cn frank.guo@bdctec.cn

Parameters

| Model |

Stroke (mm) S |

Max.Energy/Cycle (KJ) ET |

Max.Energy/Hour (KJ/h) ETC |

Max.Damping Force (KN) Fp |

Recoil Force (KN) |

Weight (Kg) |

|

| Min. | Max. | ||||||

| BHS64-50 | 50 | 0.5 | 10 | 12.5 | 65 | 148 | 3 |

| BHS90-50 | 50 | 4 | 80 | 100 | 142 | 305 | 8.5 |

| BHS90-75 | 75 | 6 | 108 | 100 | 105 | 190 | 9.5 |

| BHS90-100 | 100 | 8 | 128 | 100 | 99 | 420 | 12 |

| BHS100-50 | 50 | 4.4 | 79 | 110 | 142 | 305 | 14 |

| BHS100-100 | 100 | 8.8 | 140 | 110 | 99 | 420 | 17 |

| BHS130-70 | 70 | 10 | 170 | 179 | 182 | 425 | 21 |

| BHS130-100 | 100 | 15 | 270 | 188 | 178 | 480 | 24 |

| BHS130-150 | 150 | 21 | 294 | 175 | 183 | 535 | 28 |

| BHS170-80 | 80 | 24 | 432 | 375 | 182 | 443 | 38 |

| BHS170-150 | 150 | 45 | 630 | 375 | 183 | 535 | 48 |

| BHS190-100 | 100 | 40 | 720 | 500 | 178 | 480 | 52 |

| BHS190-150 | 150 | 60 | 840 | 500 | 183 | 535 | 64 |

| BHS220-100 | 100 | 44 | 792 | 550 | 405 | 1340 | 69 |

| BHS220-150 | 150 | 66 | 924 | 550 | 418 | 1310 | 76 |

| BHS250-100 | 100 | 60 | 1080 | 750 | 385 | 1110 | 130 |

| BHS250-150 | 150 | 90 | 1260 | 750 | 342 | 1080 | 140 |

| BHS250-200 | 200 | 120 | 1560 | 750 | 330 | 1050 | 150 |

| BHS250-300 | 300 | 180 | 2160 | 750 | 380 | 1220 | 170 |

| BHS300-150 | 150 | 117 | 1638 | 975 | 460 | 1420 | 186 |

| BHS300-250 | 250 | 180 | 2340 | 1125 | 450 | 1510 | 206 |

| BHS340-200 | 200 | 200 | 2600 | 1250 | 510 | 1620 | 275 |

| BHS340-300 | 300 | 300 | 3600 | 1250 | 490 | 1760 | 305 |

| BHS360-250 | 250 | 294 | 3822 | 1470 | 680 | 1780 | 324 |

| BHS360-400 | 400 | 470 | 4700 | 1470 | 640 | 1820 | 376 |

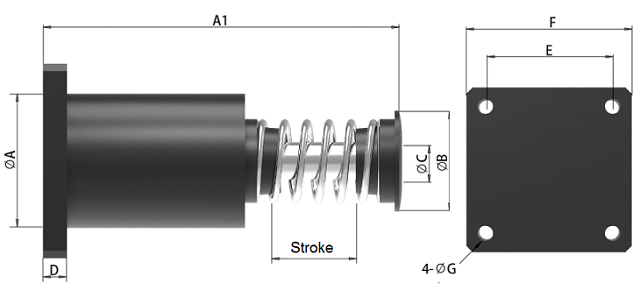

Dimension (Unit:mm)

| Model | A1 | A | B | C | D | E | F | G |

| BHS64-50 | 200 | 64 | 42 | 20 | 12 | 65 | 90 | 11 |

| BHS90-50 | 240 | 90 | 78 | 30 | 16 | 100 | 130 | 14 |

| BHS90-75 | 280 | 90 | 78 | 30 | 16 | 100 | 130 | 14 |

| BHS90-100 | 360 | 90 | 78 | 30 | 16 | 100 | 130 | 14 |

| BHS100-50 | 240 | 100 | 84 | 30 | 16 | 100 | 130 | 14 |

| BHS100-100 | 340 | 100 | 84 | 30 | 16 | 100 | 130 | 14 |

| BHS130-70 | 290 | 130 | 98 | 35 | 19 | 130 | 170 | 22 |

| BHS130-100 | 350 | 130 | 98 | 35 | 19 | 130 | 170 | 22 |

| BHS130-150 | 490 | 130 | 98 | 35 | 19 | 130 | 170 | 22 |

| BHS170-80 | 360 | 170 | 98 | 50 | 22 | 170 | 220 | 26 |

| BHS170-150 | 500 | 170 | 98 | 50 | 22 | 170 | 220 | 26 |

| BHS190-100 | 440 | 190 | 98 | 60 | 25 | 220 | 280 | 33 |

| BHS190-150 | 540 | 190 | 98 | 50 | 25 | 220 | 280 | 33 |

| BHS220-100 | 440 | 220 | 116 | 60 | 25 | 220 | 280 | 33 |

| BHS220-150 | 540 | 220 | 116 | 60 | 25 | 220 | 280 | 33 |

| BHS250-100 | 480 | 250 | 138 | 70 | 32 | 250 | 320 | 33 |

| BHS250-150 | 650 | 250 | 158 | 70 | 32 | 250 | 320 | 33 |

| BHS250-200 | 750 | 250 | 158 | 70 | 32 | 250 | 320 | 33 |

| BHS250-300 | 880 | 250 | 158 | 70 | 32 | 250 | 320 | 33 |

| BHS300-150 | 650 | 300 | 170 | 80 | 36 | 300 | 400 | 33 |

| BHS300-250 | 850 | 300 | 170 | 80 | 36 | 300 | 400 | 33 |

| BHS340-200 | 800 | 340 | 228 | 100 | 45 | 340 | 440 | 39 |

| BHS340-300 | 1000 | 340 | 228 | 100 | 45 | 340 | 440 | 39 |

| BHS360-250 | 900 | 356 | 280 | 100 | 45 | 360 | 460 | 39 |

| BHS360-400 | 1200 | 356 | 280 | 100 | 45 | 360 | 460 | 39 |

Installation request: Stroke length below 300mm, the max side load angle is 2.5°; above 300mm, the max side load angle can be 1°; make sure all set screws are fixed, recommend using thread glue.

xIn order to enlarge the buffers life span, if the buffer is used in safety emergency application, we recommend you to do the maintenance every 6 months. If the buffer is frequently used, please maintain it every month, details as below:

1. Piston Rod should be handled carefully not to be damaged or scratched, clear up the dusty and corrosive, coating oil to avoid rusty.

2. Please check rod seal to see if oil leakage or not.

3. Whenever necessary, please check the locking condition of Bolt and set screws at any time and fasten tight due to the strong impact

4. Please check the expansion & recovering status of piston rod, compare with the dimension when piston rod completely restored in catalogue. If can’t be fully restored, please add pneumatic in air bag, you can ask us to get operation manual.

QQ: 183271753

Phone: 17306109009

Tel: +86-510-88852188

Email: 183271753

Add: NO.6 Gangcheng Road,Zhongguancun Taihu Park,New District,Wuxi,China.